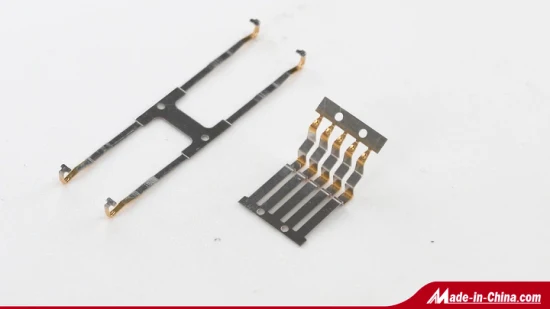

Hikvision Custom Copper Metal Stamping Hardware Parts Used on IR-Cut

Hikvision Custom Copper Metal Stamping Hardware Parts Used on IR-Cut Product Description Other similar product images Co

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | EL0077-00 |

| Fine Blanking | Double Acting |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.03-0.05mm |

| Customized | Customized |

| Surface | Punching+Electrophoresis |

| Transport Package | Tray/Carton |

| Trademark | ELMAX |

| Origin | China |

| Production Capacity | 30000pieces/Day |

Product Description

Hikvision Custom Copper Metal Stamping Hardware Parts Used on IR-Cut| STAMPING EQUIPMENT | ||

| ITEM NAME | SPECIFICATION | QUANTITY(SET) |

| Taiwan Mingxu Precision high-speed punching machine | 25T | 1 |

| Taiwan Mingxu Precision high-speed punching machine | 45T | 2 |

| Taiwan SEYI Precision punching machine | 60T | 3 |

| Taiwan SEYI Precision punching machine | 80T | 1 |

| Taiwan CHINFONG Precision punching machine | 110T | 1 |

| Wangpan precision grinding machine | 2 | |

| Wangpan precision milling machine | 2 | |

| Marriott Precision 2.5 Dimensions | 2 | |

| Marriott Precision Projector | 2 | |

| TOTAL | 8 | |

Product Description

| Product Type | metal stamping, Multistep/single Progressive Dies |

| Material | SUS301, Phosphor bronze,copper, thickness: 0.15mm-0.20mm |

| Process Methods | Punching/Stamping/Bending stamping |

| Tolerance | In general:+/-0.05 mm, can be more precision,according to your requirement. |

| Surface treatment | copper plating+nickel plating/electrophoresis |

| Applications | Mainly used in CCTV(security)camera components,Access control system |

| Delivery time | For stamping ,20-25 working days(including surface finishment) ,Mass production: 2-3 weeks |

| Advantages | Good Quality with strict inspection process/Competitive Price and prompt delivery time |

Other similar product images

Company Profile

As a one-stop OEM/ODM service provider, ELMAX has always been committing to the technology of stamping and plastic injection molding ; Focusing on tooling and mass production of Stamping parts, Injection-molded plastic parts and Insert-molding components. The products range is inclusive of hardware stamping parts, metal stamping, sheet stamping,plastic injection parts used for security camera/ CCTV camera, optical transceiver and varies of relays. The main customers of ELMAX are domestic well-known companies and partners comes from all of the world especially from Europe/America, such as FINISA, PVS, Amphenol,TTI and so on.

Metal stamping workshop

Quality guiding principle

Quality is the lifeblood of an enterprise, and customers are forever mentors.FAQ:

1: Q: Can you introduce your working process and your advantages?

A: Thanks for your question, first we will ask for your drawing, requirement, QTY and more detailed information to understand your demand and our engineer can offer the best solution according to these specifications. Sometimes we will offer the structure improvement program when we find any issue with your design or any suggestion to keep the cost down. Then we can start mould design and fabrication when the price settles down, and delivery time is approved. About our feature, we would like to say 100% quality assurance and advantage facilities can give you strong support and our professional service will lead you to make great progress on this project.2: Q: Can you ensure your production lead time and stable quality in a long-term relationship?

A: Of course. Except for the Chinese New Year holiday, our shipment is always on schedule since our scientific work arrangements, strong production competence, and our reliable employee.Thanks for your attention, why not send us your inquiry now?

Related Products

-

![10 Gauge Fuse Holder Atc/ATO, in-Line Automotive Blade Fuse Holder with Standard Car Fuses, 15A 20A 25A 30A 35A 40A Automotive Replacement Fuses]()

10 Gauge Fuse Holder Atc/ATO, in-Line Automotive Blade Fuse Holder with Standard Car Fuses, 15A 20A 25A 30A 35A 40A Automotive Replacement Fuses

-

![Light Weight Corrosion-Resistant and High-Quality Aluminum Busbar]()

Light Weight Corrosion-Resistant and High-Quality Aluminum Busbar

-

![Battery Aluminum Busbar Thermal Expansion for EV Car]()

Battery Aluminum Busbar Thermal Expansion for EV Car

-

![Pico Axial Very Fast Acting Fuse 3A 125V]()

Pico Axial Very Fast Acting Fuse 3A 125V