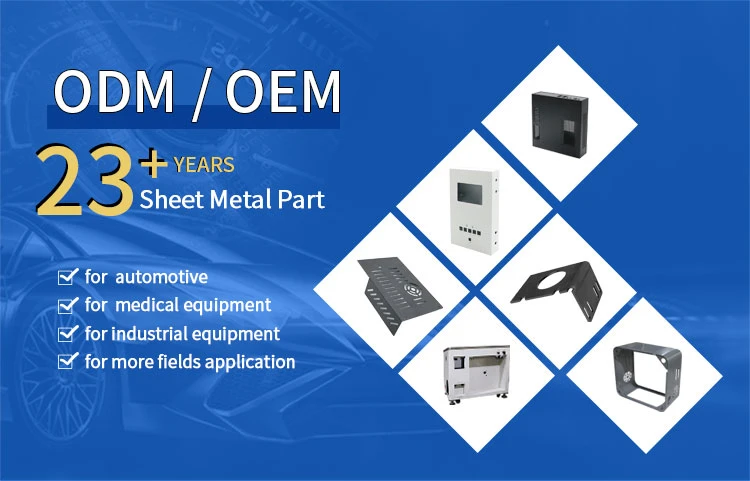

Fpic OEM Sheet Metal Fabrication Stainless Steel Stamping Parts

Overview FPIC OEM Sheet Metal Fabrication Stainless Steel Stamping PartsProduct Description Specification Company Profil

Send your inquiryDESCRIPTION

Basic Info

| Surface Finish | Electroplating |

| MOQ | 1, 000 PCS |

| Delivery Time | 10 Days |

| Sample | Free Sample |

| Our Products | Automotive Spare Parts |

| Other Services | Injection, Assembly |

| Main Used for | Electronic and Automotive |

| Package | Tape&Reel, Tray, etc. |

| Punch Qty | Almost 30 Sets |

| Location | Shenzhen, Guangdong, China. |

| Transport Package | Tape&Reel |

| Specification | OEM Automotive Spare Parts |

| Trademark | Forman |

| Origin | Shenzhen, China |

Product Description

Specification

| Our Capacity | Full-Auto Production Line for plastic injection, metal stamping, and assembly services, also the CCD inspection, |

| Our Max. Stamping Machine Tons. | 200 Tons. |

| Our Max Injection Machine Tons | 300 Tons |

| Our Production Cycles | 21 working days for the new mold and within 7 working days for the exiting model(Depends on the QTY) |

| Our Certificate | ISO9001:2015;ISO14001:2015;IATF16949:2016 |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Item | Sheet Metal Fabrication Precision Electronic Copper Stamping Metal Parts |

| Process | Automatic continuous stamping |

| Main Material | Copper Alloy, Aluminum Alloy, Stainless Steel, etc. |

| Surface Treatment | Plating, Anodized, Polished, Powder Coated, Painting, etc. |

| Mold Type | Progressive Tool |

| Other Services | Mold-making, Injection, and assembly. |

FAQ

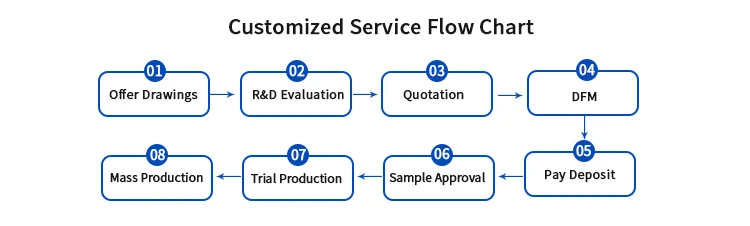

Q: Can you introduce your working process and your advantages?

A: Thanks for your question, first we will ask for your drawing, requirement, QTY, and more detailed information to understand your demand, and our engineer can offer the best solution according to these specifications. Sometimes we will offer the structure improvement program when we find any issue with your design or any suggestion to keep the cost down. Then we can start mold design and fabrication when the price settles down, delivery time is approved. About our feature, we would like to say 100% quality assurance and advantage facilities can give you strong support and our professional service will lead you to make great progress on this project

Q: Do you have any experience cooperating with brand companies?

A: Definitely yes, we are the T1 supplier of those international enterprises and Chinese companies. Always keep mutual trust and friendly relationships, thanks for their support in our 20 years of development

Q: Can you ensure your production lead time and stable quality in a long-term relationship?

A: Of course. Except for the Chinese New Year holiday, our shipment is always on the schedule of our scientific work arrangements, strong production competence, and reliable employee.

Kindly send us an inquiry ↓ to ask for more detailed information, thank you so much.